When you need to carry an oversized awkward material from one place to another, what are you planning to accomplish this task?

You will not carry the material on your head, which will be more awkward.

At this point, a clamp will be a handy tool that will let you accomplish the work without any hassle. Although you may find the task a small one, a clamp is the best solution to achieve this task hassle-free.

If you don’t know how clamps work, you will always fail to accomplish your task efficiently. So, would you love to fail?

Read this article and learn more about the working procedure of clamps.

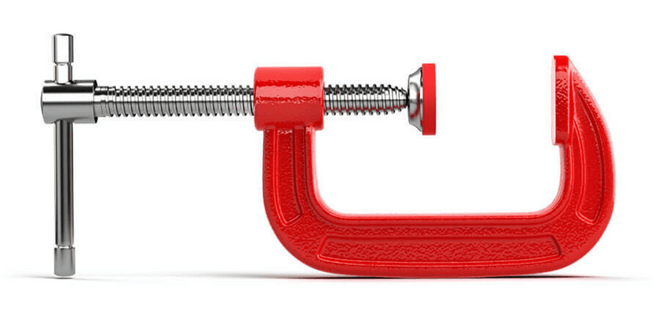

What is a Clamp?

A clamp is a tool that will assist you in fastening, securing, gripping, or temporarily carrying one or more materials.

Using this tool, you can eliminate movement among two objects to accomplish your task precisely. Also, many things are responsible for creating vibration in an object and displacing them from their workplace. Because of a clamp, the object remains stuck in its place, and you can finish your work quickly.

Clamps are easy to operate, carry, and much maintenance is unnecessary.

This is why DIY lovers and carpenters commonly use clamps in their workplaces.

Working Procedure of a Clamp

- A clamp’s prime responsibility is to gently hold an object in its place. Either you have chosen two objects to hold together or used a clamp to hold an object to its workplace; with the purpose of a clamp, a user can firmly grip the object effortlessly.

- If you own a clamp with only one jaw, then you need to use this clamp with a work surface, like a top of a bench, to grip an object securely.

- Besides, clamps with two jaws will work together to grasp an item tightly.

- Different kinds of clamp control the jaws differently. The trigger mechanism is used by some clamps, where you need to adjust the jaws following a trigger or lever.

- On the other hand, some types contain screws to adjust the clamp. When you rotate a screw, the workpiece gets closed by the clamp, which creates pressure to hold the object gently.

What are Clamps Made of?

Depending on the clamp’s type, model, and manufacture, they are made of various materials. Below I am sharing some of the most commonly used materials for making a clamp.

1. Frame

Cast Iron

The frame is the central body part of a clamp. It is made of either cast iron or steel.

Cast iron is the most common material to make a clamp frame. A combination of carbon, iron and a small volume of manganese is the active element of cast iron.

It is a form of iron where iron gets immense heat and forms liquid iron. After then, the liquid iron is poured into a mold to give it a specific shape once it becomes cool.

Iron is an ideal material to manufacture the frame of a clamp. As the frame is the central body part of a clamp, it has to be robust enough so that a user can use it frequently and it can receive much pressure.

Steel

Another material for manufacturing the clamp frame is steel. Steel is a well-known mixture of iron and carbon.

Steel’s best feature is its corrosion-free and excellent tensile strength. For this reason, it is a widely used material at any construction site.

The steel, which is used in the frame of the clamp, is generally forged, a process by which the metal is designed following compressive forces.

Forced steel confirms the body will be high in quality and sturdy. Due to these characteristics of steel, steel-made clamps can bear heavy pressure on them.

2. Jaws

The majority of the jaws are made of steel. However, some models are also available where iron creates a jaw.

Steel-made jaw confirms; they also can bear heavy pressure with solid character.

One drawback of iron-made jaws is that if the clamp body frame is made of wood or other materials except for steel, jaw pads must be used to cover up the jaws. Otherwise, the possibility of damage is high.

3. Screw

Steel is the ideal material to make the screw of a clamp.

If any other material is used, the screw will not last long. It is expected the screw will bear the force that it receives while clamping a workpiece.

To enhance the strength of a screw, sometimes, they receive a coating of chrome. Also, this coating assists them in not rust over time.

4. Handle

The handle of the clamp is made of the below materials

Steel

The sliding-pin style handle is quite popular in a clamp. These handles are made from steel, and some models are chrome coated.

Plastic

Plastic is the most commonly used material for clamp handles.

The advantage of plastic is that it is highly durable, easy to grip, and ergonomically shaped so that a user feels comfortable using it.

Besides, plastic handles will contain rubber covers on them for additional grip.

Wood

Wood is an alternative material for a clamp handle. However, it is not as popular as the other two materials because wooden handles may slip when tightening the clamp.

5. Strap

Some clamp models also contain a belt that is made of nylon. Nylon is an exceptionally long-lasting material.

Conclusion

While operating clamps, ensure your fingers are safe from being pinched by the frame, jaws, or screws. Learning a new thing is always excellent, and I believe this article will assist you a lot in making your work more comfortable than before.