Choosing a welder requires the user to consider different factors to pick the perfect task. A welder is either a gas or an arc welder. Selecting the best between the two needs to check the tool’s efficiency and reliability to reduce incurring maintainable costs.

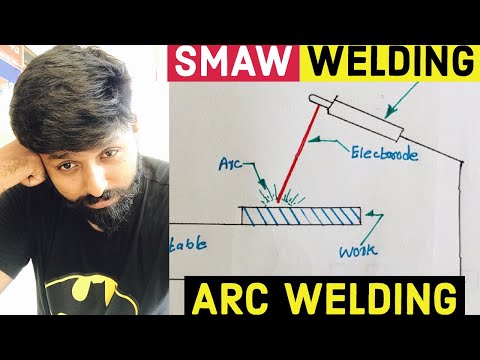

An arc welder uses an electric arc to fix metals; the only task is choosing the best arc welder to accomplish the welding task. Reading the article to the end on what kind of welder I need is important for efficient operation.

The tool is efficient, and its operation is easy. An arc welder is cheap, making it affordable even to low-income earners.

The tool is portable, making transport from one place to another easy. An arc welder is the perfect type of welder you need to complete the task for perfect results.

Types Of Arc Welders

Stick welder

The welder uses a welding rod coated in flux, acting as the electrode, and conducts electricity, creating an arc that melts the metal.

Welding rods vary in length and diameter depending on the type of metal.

Thicker rods are applied to hard metals and thick pieces. The rods wear out and may need frequent replacement. Stick welders are cheap and straightforward, which makes maintenance easy.

Stick welding needs some practice to master and perfect since you must obtain a perfect angle between the metal and the rod. Notably, the amperage must match the rod’s diameter to prevent the metal’s rapid burning.

Instead of introducing a join on metals, high amperage melts holes into the metal. Low amperage makes the rod stick to the metal, meaning it must match the metal and type size.

TIG welder

The Tungsten Inert Gas welder requires a professional and robotic welder. TIG welders use a tungsten electrode and generate the electric arc.

A nozzle concentrates inert shielding gas to the weld and protects it from contaminants.

It may take time to master the TIG welding process, mainly controlling the angle and electrode gap.

However, it is worth it because of several advantages in various applications. TIG welder works on any type and size of metal.

The tungsten electrode also ensures precise welds on thin metals by reducing burning. Production of little to no slag produces a neat weld. Therefore, you do not have to clean afterwards.

MIG welder

The Metal Inert Gas welders use a wire that melts into the weld. Inert shielding gas ensures the protection of the weld.

The Metal Inert Gas welders use a wire that melts into the weld. Inert shielding gas ensures the protection of the weld.

Gas generation occurs from a nozzle at the electrode or within the core flux wire.

Notably, the welding is strong, ductile, and easy to learn. That is why most beginner prefers MIG as a beginner welder.

Furthermore, adjusting the wire feed rate to match your welding speed is possible. Observing the electrode gap or angle is not compulsory.

You have to run the wire into the gap between the metal surfaces at a steady speed. MiG welding is best applicable for thin metals, alloys, and aluminum.

Inverter welders

An inverter welder uses a similar essential operation of a transformer, an additional benefit of an inverter under a computer’s control.

The tool has high efficiency, thus using less electricity and reducing heat given off inside the welder. Therefore, inverter welders have a long cycle of duty.

Monitoring the current given off by the tool makes it easier to use. Additionally, voltage and amperage stay stable, making burning or sticking impossible. The inverter welder is light, which makes it easily portable.

Welder Plasma Cutter Combos

The tool is the best for cutting metal, using heat for a perfect and precise cut. It has limits to the thickness of metal it cuts depending on the power of the electric arc given off. The absence of rough edges to metal means no grinding or sanding.

Therefore, it does not interfere with the quality of the metal or cause stuttering. A plasma cutter combines multiple tasks because it cuts metals and, at the same time, performs welding.

The plasma cutter combo takes up less space, saving the user from the trouble of storage. Purchasing the tool is cheaper than buying two separate tools.

Benefits Of An Arc Welder

It is affordable

Arc welders are cheap, favouring even low-income earners since equipment costs are not high. Additionally, the welders require less protective equipment because there is no gas production during welding.

It is portable

The gadgets are lightweight and make transportation easier. Therefore, a welder does not need to acquire several arc welders to work in different places, saving on expenditure and cost.

Works on any metal

Arc welders produce enough current to work even on thick and hard metal. When welding thin metal, regulating the current helps produce perfect results. Additionally, the welders work on dirty metal, making recycling possible and, in turn, saving on expenditure.

Applicable under any weather conditions

Arc welders give perfect results whether it is windy or rainy. Therefore, shielding gas is not compulsory, and splatter should not cause worries. The welders help the user complete the welding task without struggling to give perfect results.

Final Thought

The versatility of an arc welder makes it the best choice. It works on both thick and thin metals. You may also use the tool on hard and soft metals and end up with a permanent and robust connection. Using the tool is possible anytime since shielding gas is unnecessary, even on a windy day.

Arc welders give clean results since they produce no slater, saving the user the trouble of cleaning up after welding. The tool’s portability saves on cost because carrying it around is easy, meaning enough to accomplish welding in different areas.

Additionally, you must not have a high income to afford an arc welder because it is cheap. I am visiting the website to get more information on what kind of welder I need and why it is the best choice.